U Purline Metal Roll Forming Systems with GCr15 Bearing Steel

| Place of Origin: | Guangdong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

U Purline Metal Roll Forming Systems with GCr15 Bearing Steel

<span style

U Purline Metal Roll Forming Systems with GCr15 Bearing Steel

Product Features of U Shaped Purlin Roll Forming Machine

1.The machine is full-automatically controlled by PLC, the whole hydraulic transmission, drive hydraulic oil jar carry out and shearthrough center pump station towards the hole, hydraulic pressure Motortransmit power as main transmission, characteristic its reliable for tooperate steadily by hydraulic pressure, shear towards hole precision geometry form rule of the notch. Its hydraulic pressure transmission,two sete correct and fit.

2.U purline Forming Machine can produce many types of U-shaped purline.The whole line mainly consists of uncoiler and its base, coil sheetflattening equipment, punching equipment, pre-cutting equipment,C-shape forming system, hydraulic station, and PLC controlling system

3.sandwich panel machine.sandwich panel machinery,roll foaming machine

Technical Data of C Shaped Purlin Roll Forming Machine

| No. | Items |

Type Unit |

Specification |

| 1 | Size | mm | 19000×1200×1400 |

| 2 | Weight | kg | 11000 |

| 3 | Width | mm | 100 ~ 472 |

| 4 | Thickness | mm | 1.6-3.2 |

| 5 | Main motor power | kw | 7.5 |

| 6 | Working Speed | m/min | 16-18 |

| 7 | Stand of forming machine | stands | 19 |

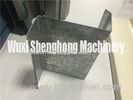

| 8 | Product specification | mm | (80×50×15)~ (300×80×20) |

| 9 | Suitable Material | Colored galvanized steel board | |

| 10 | Controlling system | PLC |

Specifications

C Z U Shaped Steel Purlin Roll Forming Machinebiggest and most competitive machinery manufacturer in China, C Z U Purlin Machine are widely used as the supporter of roof and wall in large-scale and mid-scale construction, such as factories,warehouses, garages, exhibition centers, cinemas, theatres and gardens. The products of U, C, Z shape purlin forming machine have excellent anti-bending property and are easy to install.

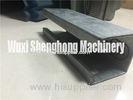

Purlin Channeling Machine Working Flow

Decoiling the sheet-sheet guiding -coil strip leveling-roll forming-punching for horizontal hole-punching for vertical hole-measure length-cutting the panel-panels to the supporter

Material of Main Equipment

|

Roller Material |

GCr15 bearing steel, with quenching treatment. |

|

Active Shaft Material |

High grade No.45 carbon wrought steel,which can improve the integrated mechanic feature of the shaft. |

|

Electric Elements |

PLC control panel, transducer imported from Mitsubishi of Japan. |

|

Cutter blades |

Cr12 mould steel with quenched treatment. |

Packaging & Delivery

|

Packaging Details: |

1. Export standard package for container |

|---|---|

|

Delivery Detail: |

about 40 days |

Machinery Shows

Related Search

Find more related products in following catalogs on Hisupplier.com

Related Products

Company Info

Wuxi shenghong machinery co.,ltd [China (Mainland)]

Business Type:Manufacturer

City: Wuxi

Province/State: Jiangsu

Country/Region: China (Mainland)