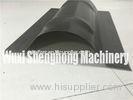

11kw Color Steel Roof Roll Forming Machine With 12 Months Warranty

| Place of Origin: | Guangdong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

11kw Color Steel Roof Roll Forming Machine With 12 Months Warranty

11kw Color Steel Roof Roll Forming Machine With 12 Months Warranty

Component and Function

| Coil Feeding Equipment | Consists of one uncoiler with capacity of 5000kgs and its base. The steel sheet is manually fed to the guiding equipment under the function of friction and traction |

| Guiding Equipment | Adopting guiding bar and sliding block to control the width and position of the steel sheet. The coil is guided in the correct position and passed to the roll forming equipment. |

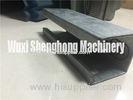

| Mainframe Transmission | Transfer the main motor power to the rollers through chains and sprockets, and also transfer the coil sheet. |

| Roll forming system |

The main frame of machine is welded separately and the outside wall is connected by screw after being rotoblasted on the surface.The rollers are surface-chromeplated after being machined by the exact machine tool. |

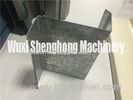

| Pressing equipment | After formed the shape of the tile panel, pressing the tile panel with pressing equipment which ensures the shape lasting and more beautiful. |

| Post Cut Equipment | The length and blocks can be set by the buyer through the control panel, when reach the set length, the machine will cut the panel automatically. The cutting is finished under the power of hydraulic station which guarantees the precision of cutting. |

| Hydraulic Station | Supplies the initial power to the cuter through a closed oil tank. It is off without cutting, which can save the power. |

| PLC Control Panel | The electric controlling system of this machine consists of five parts: operating system, screen, PLC, transducer and strong electricity part. The controlling system of this machine are imported from Mitsubishi company of Japan. The system uses modularized structure and has convenient, reasonable, canonical wiring arrangement, and its maintenance is quite easy. The independent operating console facilitates the mutual dialogue between the operator and the machine. The operation is easy and steady and can be choosed operation by manual or automatically. |

Quick Details

- Production Capacity: 2.0-3.0m/min or high speed solution

- Place of Origin: Jiangsu, China (Mainland)

- Brand Name: SHENGHONG

- Power(W): 11

- Voltage: 380V 50Hz 3phases or as your requirement

- Dimension(L*W*H): 6500*1300*1100

- Condition: New

- Type: Tile Forming Machine

- Use: Roof

- Weight: About 8000

- cutting type: hydraulic type

- properties: fast speed

- application: roof and wall and step

- material: PPGI GI

- warrant: 12 months

- control system: PLC

- tile type: steel

- Certification: CE

- Warranty: 1year

- After-sales Service Provided: Engineers available to service machinery overseas

- type: roof tile machine roll forming machine color roof

- machine color: according to your requirement

- life time: about 10 years

Advanced Roof Cold-rolling Form Machine Introduction

Wuxi Shenghong Roof series roll forming machine consists of uncoiler and its base, infeed guides, fixed position driven forming stations, shearing device, hydraulic station, PLC control console and so on. Our company has hundreds of profile models for this series roll forming machine, such as SHRF25-248-992, SHRF50-250-1000, SHRF18-76-988, and etc. We can design different kinds of profile and fittings for machine, as per customers' requirements.

Designated use

- Some final products for Automobile.

- Some final products for Building, such as for Roofing / Ceiling / Wall materials, and dry wall (track and stud) material.

- Some final products for Gate-Panel, Guard-Panel and sound insulation

Our Pursuit

Stable Pursuit: We walk on a series and boutique product route to meet the medium and high market demands and shall be committed to developing high and medium-end compound and welding production equipment. Meanwhile, we also expand global marketing network actively. Our business planning is: To be export-oriented and strive to become an influential first-class enterprise in Zhejiang and even East China region.

Integration of Resources - Resource integration is a measure to adjust business strategy and also the daily work of business management. Integrity means optimizing resource allocation, that is, to obtain the best overall result. A business should make identification, selection, absorbing, allocation, activation and organic integration to its resources from different sources, at different levels, of different structures and with different contents, so as to make the resource more flexible, more rational, more systematic and more valuable.

Constant Progress – If a person has sufficient faith, then he can create wonder, so does a business.

Priority Development – As a business making continuous progress, we shall make constant development and perfection in terms of technical personnel and make unremitting efforts to become a standard high-tech enterprise in new materials used in special equipment for steel-structure buildings and steel structures.

Machinery Shows

Workshop Show

Related Search

Find more related products in following catalogs on Hisupplier.com

Related Products

Company Info

Wuxi shenghong machinery co.,ltd [China (Mainland)]

Business Type:Manufacturer

City: Wuxi

Province/State: Jiangsu

Country/Region: China (Mainland)