Ceiling Channel Roll Forming Machine / Roofing Sheet Making Machine

| Place of Origin: | Guangdong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

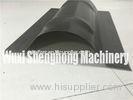

Ceiling Channel Roll Forming Machine / Roofing Sheet Making Machine

Ceiling Channel Roll Forming Machine / Roofing Sheet Making Machine

Roof & wall Roll Forming Machine Introduction

Wuxi Shenghong Roof & wall series roll forming machine consists of uncoiler and its base, infeed guides, fixed position driven forming stations, shearing device, hydraulic station, PLC control console and so on. Our company has hundreds of profile models for this series roll forming machine, such as SHRF25-248-992, SHRF50-250-1000, SHRF18-76-988, and etc. We can design different kinds of profile and fittings for machine, as per customers' requirements.

Component and Function

1. Sheet guiding equipment: Using guiding equipment of leader sliding block style. The width and the left or right position can be adjusted only by adjusting the leader, then the sliding block can realize left or right movement.

2. Mainframe Transmission: Transfer the main motor power to the rollers through chains and sprockets, and also transfer the coil sheet.

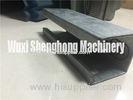

3. Roll forming system: The main frame of machine is welded separately and the outside wall is connected by screw after being roto-blasted on the surface. The rollers are surface-chrome plated after being machined by the exact machine tool..

Designated use

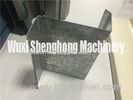

1. Some final products for Automobile.

2. Some final products for Building, such as for Roofing / Ceiling / Wall materials, and dry wall (track and stud) material.

3. Some final products for Gate-Panel, Guard-Panel and sound insulation

Technical Parameters

1) automatic inner tight decoiler

A. Coil inner diameter: 450mm-700mm

B. Max width of coiling: 1200mm

C. Max weight of loading: 6000kg

D.Thickness:0.3-0.7mm

2) Main forming machine

A. Number of forming steps: according to the profile drawings

B. Material of shaft : 45# steel adjustable treatment. Outer diameter: 70mm

C. Material of roller : High grade 45# steel(plated chrome on surface)

D. Main motor power : 7.5kw

E. Forming speed : 10-16m/min

F. Stand : 350# steel welding

G. The plating chromium of roller surface : 0.05mm

3) hydraulic cutter

A. Material of blade: Cr12 with quenched treatment60-62º C

B. Cutting system: Adopt advanced hydraulic drive, automatic cut after forming, no distortion, no waste, high safe factor and then cuts

Reference information

- Warranty: 12 months

- After-sales Service Provided: Engineers available to service machinery overseas

- Color: As your requirements

- Cutting type: hydraulic cutting

- Control: PLC control system

- Raw material : color steel, galvanized steel

- ODM : Available

- OEM : We can product as your requirements

- Condition: New

- Type: Tile Forming Machine

- Tile Type: Steel

- Use: Roof

Machinery Shows

Related Search

Find more related products in following catalogs on Hisupplier.com

Company Info

Wuxi shenghong machinery co.,ltd [China (Mainland)]

Business Type:Manufacturer

City: Wuxi

Province/State: Jiangsu

Country/Region: China (Mainland)