18.5 KW Metal Deck Roll Forming Machine High Strength with Big Rib

| Place of Origin: | Guangdong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

18.5 KW Metal Deck Roll Forming Machine High Strength with Bi

18.5 KW Metal Deck Roll Forming Machine High Strength with Big Rib

Introduction

Floor decking forming machine consists of uncoiler and its base, coil sheet guiding equipment, roll forming system, post-cutting equipment, hydraulic station, controlling system, supporter table. The corrugated profile sheet produced by this machine has high strength with big rib, which adheres well to concrete. It’s best to be used as the floor of high buildings, and the cost of such floor is low.

Technical Parameters

| Material Spec Thickness of Coil Sheet Main Motor Power Forming Speed Hydraulic Station Power Quantity of Stands Hydraulic Pressure Controlling System Index Error of Length Total Weight Voltage |

: Galvanized steel sheet : 0.8 --1.2 mm : 18.5kw : 10--12m/min : 3kw : About 24 groups : 10~12Mpa : PLC : 10m±2mm : About 1800kg : 380V 3 phase 60Hz or to the buyer's requirement |

Standard Equipment of Machine

| Passive uncoiler Guiding equipment Rolling forming equipment Pressing equipment Post-cut equipment Hydraulic station PLC controlling desk Supporter table Security cover (optional) |

: 1pcs : 1set : 1set : 1set : 1set : 1pcs : 1 pcs : 2 pcs : 1set |

| Further Information of Steel Floor Decking Sheet Machine |

Steel floor decking sheet is rolled by series steel floor decking roll forming machine, the finished products are of many features, such as simple shape, large wave height, high intensity and good adhesiveness when pouring the concrete together with the welded steel wire net on-site. In the high-storey building, it not only can save steel mould board, but also reduce the bearing of the floor; on basis of equal capacity, it reduces the steel amount of engineering useage, so that it saves cost of investment.

Steel floor deck roll forming machine consists of uncoiler and its base, infeed guides, fixed position driven forming stations, shearing device, hydraulic station, PLC control console and so on. Our company has dozens of profile models for this series roll forming machine, such as WLFD66-225-675, WLFD76-344-688, and etc. We can design different kinds of profile and fittings for downpipe machine, as per customers' requirements.

| Working Flow |

Uncoiling→Sheet Guiding→Straightening &Levelling→(Hole Punching)→Measuring Length &Shearing→Roll Forming→Sheet to support table.

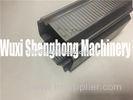

Profiles show

Decking Sheet Application

Related Search

Find more related products in following catalogs on Hisupplier.com

Related Products

Company Info

Wuxi shenghong machinery co.,ltd [China (Mainland)]

Business Type:Manufacturer

City: Wuxi

Province/State: Jiangsu

Country/Region: China (Mainland)